CAPSTONE LESSON

www.iqytechnicalcollege.com/CapstoneLesson.pdf

www.iqytechnicalcollege.com/CapstoneLesson.htm

UEENEEG105A

http://www.highlightcomputer.com/electricaltrade2021.htm#G105

UEEEL0039

1.Prepare to design, install,

inspect and test an electrical installation

UEEEL0039

5. Visually

inspect and conduct safety testing on electrical installation

VISUAL

INSPECTION

|

Portable Electrical Equipment |

Yes |

No |

|

1. Is there damage (apart from light scuffing)

to the cable sheath? |

|

|

|

2. Is the plug damaged (eg.

the casing cracked or pins bent)? |

|

|

|

3. Are there inadequate joints, including

taped joints, in the cable? |

|

|

|

4. Is the coloured

insulation of the internal cable cores showing where they enter the plug? |

|

|

|

5. Does the appliance appear to have been

subjected to conditions for which it is not suitable (eg.

is it wet or excessively contaminated)? |

|

|

|

6. Is there damage to the external casing

of the equipment or are there loose screws or parts etc? |

|

|

|

7. Is there evidence of overheating (eg. burn marks or discoloration)? |

|

|

|

8. Is the main on/off switch damaged, does

it operate incorrectly? |

|

|

|

Notes: |

||

An answer “Yes” to any of the above

indicates that the appliance is potentially dangerous and must be taken out of

use.

|

General

Electrical Inspection: Visual inspection of electrical equipment may include

the following: |

Yes |

No |

|

1. Flexible cords in good condition ie look for cuts, abrasion or damage |

|

|

|

2. External components or casing are not damaged (these

may form part of the insulation) |

|

|

|

3. Power and extension cords anchored and separated from

other hazards such as liquids, mechanical action or

traffic areas. |

|

|

|

4. Covers, guards, controls, alarms

or mechanical safety features are in good condition |

|

|

|

5. Power outlets and power boards are not overloaded. |

|

|

|

6. Cords are kept away from traffic areas. |

|

|

|

7. Electric cords and wiring are not kept under carpets

where they are subject to wear and tear |

|

|

|

8. Electric cords and wiring are not run through windows

or doorways where they are subject to abrasion |

|

|

|

9. Double adapters are not used (power-boards should be

used) |

|

|

|

10. Bar radiators and para-flood lamps are not used for

heating purposes |

|

|

|

11. Appropriate electrical equipment are

used in wet areas such as around sinks and in toilets |

|

|

|

12. Only designated electrical appliances, equipment, or

extension cords are used in areas which contain dangerous or hazardous

materials (flammable, explosive, or corrosive) |

|

|

|

Notes: |

||

Continuity of Main Earth and

Bonds

Which Earth Continuity Test

·

·

Which Earth

Continuity Test?

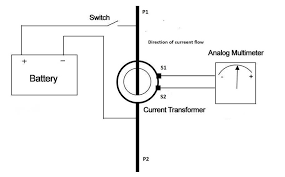

The

earth continuity test is a designed to test the resistance of the protective

earth of an appliance and/or the supply lead. It is measured between any

accessible earthed parts and the earth pin of the plug.

The

test is based on the principles of Ohm’s Law.

By

applying a known voltage and current, the resistance can be calculated using

the formula Voltage ÷ Amps = Resistance ( Ω ).

When

performing the earth continuity test you have three options for the test

current you apply.

- 12 V

maximum, test current in the range 100 to 200 mA; commonly known as “screen test”

- 12 V

maximum, test current of 10 A ( rarely used )

- 12 V

maximum, test current of 1.5 times the rated current of the appliance or

25 A, whichever is the greater; commonly known as

a “bond test”

Most

portable appliance testers (PATs), including multimeters,

should be able to perform the screen test. The screen test is useful for detecting poor

connections of the earth conductor to either the chassis or the earth pin of

the plug, commonly due to a loose connection or corrosion; the low current

being applied makes it fairly sensitive to increases

in resistance.

The bond test is useful for

detecting defects such as breaks in the strands of the earth conductor or

connections that can’t handle the maximum potential current load that could go

through the earth conductor; the higher current being applied would result in

high resistance reading.

When

there is resistance to the current flow the energy is converted into heat. The

heat may be great enough to cause the filaments to melt. Here are two examples

to demonstrate how you could have a situation where

performing one type of test could produce a pass and the other test would

produce a fail.

Example 1 The earth connection to the chassis of the appliance is corroded.

This could inhibit the flow of the low test current

used with the screen test and result in high resistance readings. However the test current used in the bond test is

significantly higher and it could “ram through” like a Mac truck with little

resistance. In this case, the screen test would be the best choice as it would

detect the defect.

Example 2 The connection to the earth pin is held in place by only a

few strands. The screen test would produce a pass as there are enough strands

to allow the current to flow with little resistance, however there are not

enough strands for the higher test current of the bond test to flow unimpeded.

This resistance could cause the strands to get so hot they melt and produce a

very high resistance reading. In this case, the bond test would be the best

choice.

Summary As you can see from these two common examples neither test

can detect all possible earthing defects, each test has their own pros and

cons.

So which should you use? Unfortunately

there is no right or wrong answer. You may in fact want to perform both. Don’t

be too concerned about performing the bond test on IT equipment. I have done

thousands of these without any damage occurring to the appliance(s) and believe

it doesn’t pose a risk to the appliance provided you do it correctly.

Further

reading: Standard AS/NZS 3760 Appendix

D

Learn How To Test and Tag – In-Service

Inspection and Safety Inspection of Electrical Appliances And Cord Sets to

AS/NZS 3760 Click here>> Test Tag Courses

For all protective conductors,

including main and supplementary bonding conductors, electricians must

perform a continuity test using a low-reading ohmmeter. For main equipotential

bonding, there is no single fixed value of resistance above which the conductor

would be deemed unsuitable. [See European terminology list at end of

article]

[Introduction photograph.

Continuity of protective conductors (Photo credit: tradeskills4u.co.uk)]

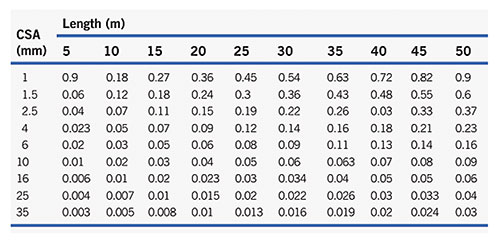

Each measured value, if

indeed it is measurable for very short lengths, should be compared with the

relevant value for a particular conductor length and size. Such values are

shown in Table 1.

Table

1. Resistance (O) of Copper Conductors at 20°C

Table

1. Resistance (O) of Copper Conductors at 20°C

Where a supplementary

protective bonding conductor has been installed between simultaneously

accessible exposed and extraneous conductive parts the resistance of the

conductor R must be equal to or less than 50/ Ia.

So, R ≤ 50/Ia, where 50 is the voltage, above which exposed metalwork

should not rise and Ia is the minimum current,

causing operation of the circuit protective device within

5s. For

example, suppose a 45 A BS 3036 fuse

protects a cooker circuit, the disconnection time for the circuit cannot be

met, and so a supplementary bonding conductor has been installed between the

cooker case and the adjacent metal sink.

The resistance R of that conductor

should not be greater than 50/ Ia, which in this case is

145 A (IEE Regulations). So:

50/145 =

0.34 Ω

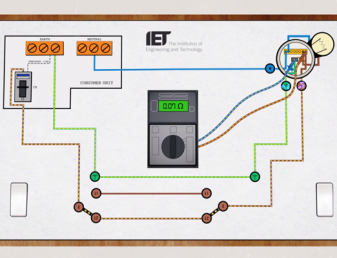

How

then do we conduct a test to establish continuity of main or supplementary

bonding conductors?

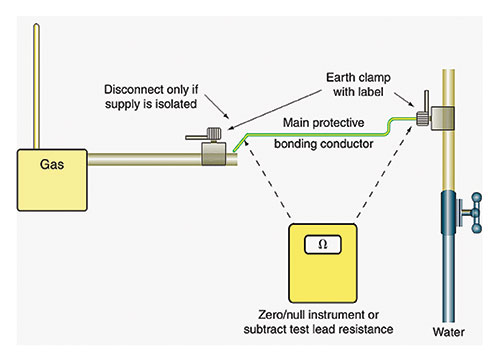

Quite simple really, just

connect the leads from the continuity tester to the ends of the bonding

conductor (figure 1). One end should be disconnected from its bonding clamp;

otherwise, any measurement may include the resistance of parallel paths of

other earthed metalwork.

Figure

1. Continuity of main protective bonding conductors

Figure

1. Continuity of main protective bonding conductors

Remember to zero the

instrument first or, if this facility is not available, record the resistance

of the test leads so that this value can be subtracted from the test reading.

Important

Note:

If the installation is in

operation, never disconnect main bonding conductors unless the supply can be

isolated. Without isolation, persons and livestock are at risk of electric

shock.

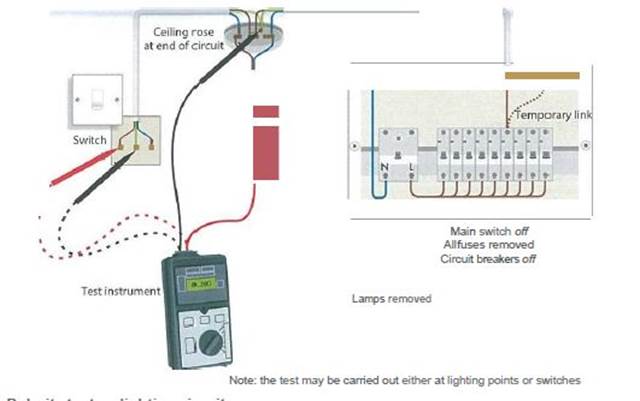

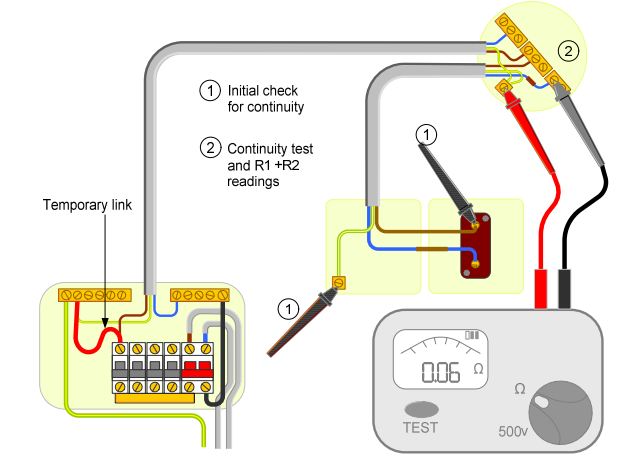

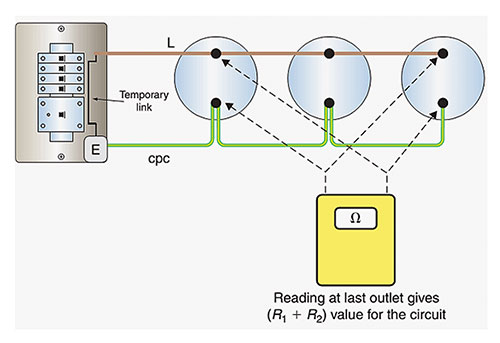

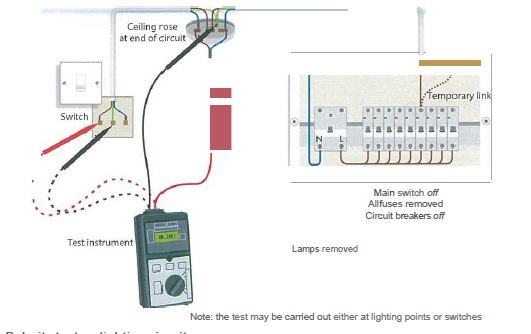

The continuity of circuit

protective conductors (CPCs) may be established in the same way, but a second

method is preferable, as the results of this second test indicate the value of

(R1+R2) for the circuit in question.

The test is conducted in

the following way (Figure 2):

- Temporarily link together the line

conductor and CPC of the circuit concerned in the distribution board or

consumer unit.

- Test between line and CPC at each outlet

in the circuit. A reading indicates continuity.

- Record the test result obtained at the

furthest point in the circuit. This value is (R1+R2) for the circuit.

Figure

2. Circuit protective conductors (CPC) continuity

Figure

2. Circuit protective conductors (CPC) continuity

There may be some difficulty

in determining the (R1+R2) values of circuits in installations that comprise

steel conduit and trunking and/or steel wire armoured

(SWA) cables and mineral-insulated metal-sheathed (MIMS) cables because of the

parallel earth paths that are likely to exist.

In these cases, continuity

tests may have to be carried out at the installation stage before accessories

are connected or terminations made off as well as after completion.

Terminology

in Europe:

Supplementary

bonding. Green and yellow conductors that connect accessible metal parts

of electrical equipment (such as a heated towel rail) to accessible metal parts

of items of electrical equipment and/or accessible metal parts of items that

are not electrical (such as pipes). These connections are made to prevent a

dangerous voltage between two accessible metal parts, in case

there is a fault. You may need supplementary bonding for rooms containing a

bath or shower, except where all circuits in the room are RCD protected and the

main bonding is up to the required standard.

Residual

current devices (RCDs). A sensitive switching device that trips a circuit

when it finds an earth fault.

The

circuit protective conductor(increasingly called the ‘c.p.c.’) is a system of conductors joining together all exposed conductive

parts and connecting them to the main earthing terminal. Strictly speaking, the

term includes the earthing conductor as well as the equipotential bonding

conductors.

Video

https://www.youtube.com/watch?v=ScD3Y1Ty5n8

https://www.youtube.com/watch?v=R2XygQfgJao

https://www.youtube.com/watch?v=rnvNfI__kYU

https://www.youtube.com/watch?v=u5SCOb4dBus

https://www.youtube.com/watch?v=Ipo-veJdiTc

https://www.youtube.com/watch?v=2H8ATUWefSk

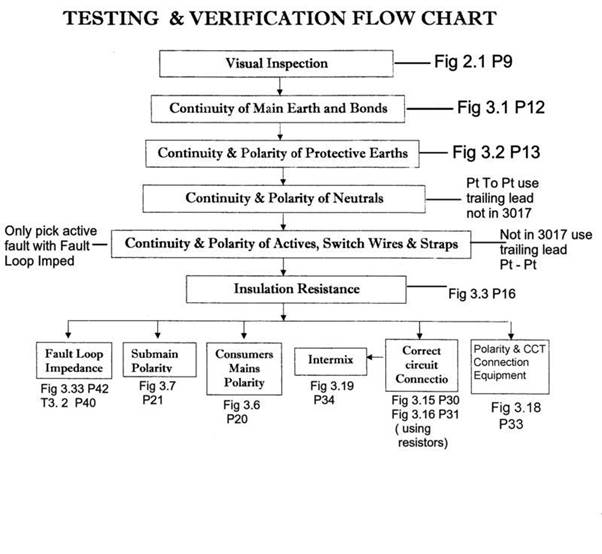

Continuity and Polarity of

Protective Earth

Testing requirements for an installation

When carrying out testing on a new installation or when

alterations/additions are made to an installation, a suggested sequence of

testing as per AS/NZS 3000:2018 Section 8 would

be as follows:

- Visual

inspection of works carried out

- Earth

resistance test – continuity of the main earthing conductor

- Earth

resistance test for other earthed and equipotential bonded parts

- Insulation

resistance test of installation

- Polarity

and connections test of circuits/wiring installed e.g.

consumers mains, submains or sub-circuits.

- Earth

fault loop impedence test

- Verification

of operation of residual current devices

Further information can be found under AS/NZS 3000:2018 Section 8:

Verification.

When carrying out testing ensure all test results are recorded and

records are maintained for 5 years. (ELR 1991 Reg 52

(2D)

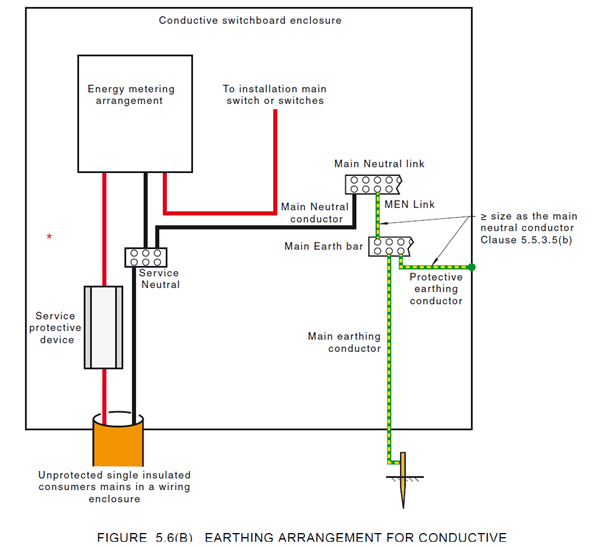

Recently during inspections being carried out it has been found that the

MEN connection has been missed during checking and testing on several installation

inspections. This is regarded as a serious defect. Reason given for this has

been that it is no longer a requirement to carry out earth fault loop impedence tests as circuits are now covered by RCD and the

test is no longer required.

Electrical contractors and electrical workers are reminded that while

RCDs can be used to achieve automatic disconnection of supply, RCDs fitted

to circuits are intended only to augment other measures of basic protection and

that RCD’s are additional circuit protection to that of the primary circuit

protection. (AS/NZS 3000:2018 clause 2.4.1, 2.6.1)

The operation of the circuit protection is reliant upon the integrity of

the MEN connection and the supply neutral (PEN) conductors. If the value of the

earth fault loop impedance exceeds that of Table 8.1 AS/NZS 3000:2018 then

correct operation of the primary circuit device may not be achieved. Further

information on this can be found under Appendix B, B4: Protection by automatic

disconnection of supply.

When completing the Electrical Safety Certificate and/or Notice of completion for electrical works carried out,

electrical contractors and workers are again reminded to ensure that when

completing section 4E as the completing electrical worker and signing off as

the nominee that all electrical work has been checked, tested, test results

recorded and certified safe to operate when connected to supply. (AS/NZS

3000:2018 clause 2.1.2 and 4.1.2, E(L)R 1991 Reg 49, 49B, 52(2B), 52(2D) and

52B.)

Note: Under certain circumstances a test for fault loop impedance could

give a false impression that a MEN is present, therefore a visual confirmation

of the MEN is essential.

Video

https://www.youtube.com/watch?v=LcJu2tlhpiI

https://www.youtube.com/watch?v=vtyPt9MVUbA

https://www.youtube.com/watch?v=dMtxkhL6c8I

https://www.youtube.com/watch?v=X5VEtGTSrwg

Continuity and polarity of

active switch wire and Straps

What is polarity testing?

Polarity testing is one of the tests that are required for

initial testing of the installation under IEC 60364 standard.

This test

will verify that all the switches installed in the system are connected in

current carrying conductor and not in neutral. For example, if you isolate

or switch the neutral of a circuit via a single-pole circuit breaker or switch,

it would appear that the circuit is dead where in fact

it is still live.

|

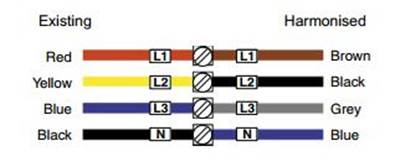

source: TLC-Direct UK |

If polarity is not correctly determined there may be a risk of electric

shock during maintenance procedures.

This would not be the case, as live conductors and connections

would be present at fixed equipment, sockets and

switches - this would be very dangerous.

There are three recognized methods of

evaluation. All three methods have their advantages and possible dangers, if they are not carried out correctly.

Methods of polarity testing

1. Polarity by visual inspection

By using your knowledge and sight, correct termination of cables relating to

core colors can be established.

It is essential that polarity is checked visually during the

process of installation, especially in cases where checking by testing is

impractical.

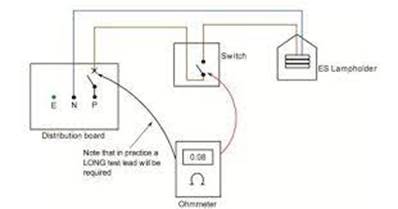

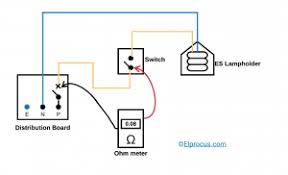

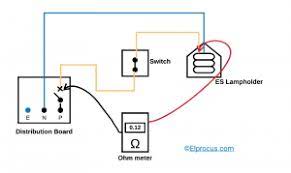

2. Polarity by continuity testing

If visual inspection is not possible, you will need to use a

low-resistance ohmmeter for this test. When you

continuity test radial and ring final circuits, part of the process is to test

and visually inspect the polarity of fixed equipment and socket outlets.

|

|

|

Polarity testing using low resistance ohmmeter |

Steps:

- Switch off the circuit breaker supplying

the circuit.

- From the specific circuit, put a temporary

link that will connect the line conductor and the CPC or any equipotential

bonding conductors. It will serve as a testing point for convenience

- Conduct continuity testing by placing the

test leads across the line conductor and the nearest

CPC or any exposed conductive parts of the circuit.

- If the instrument shows zero reading (with

continuity sound) then the switch is connected properly to the line

conductor.

- If the instrument shows some significant

ohmic value then the switch is not connected to

the line conductor. Interchange the connections to fix the problem.

3. Live testing for polarity

If the two methods are not possible due to urgency we can

perform live polarity testing by using the approved voltage GS38.

Steps:

1. Test between LINE and NEUTRAL terminals

2. Test between LINE and EARTH terminals.

3. Test between NEUTRAL and EARTH terminals

The test instrument should indicate full voltage (230V) between Line-Neutral and Line-Earth

conductors. No voltage should be detected between Neutral-Earth.

Source:

- City and Guilds

- BS 7671

- TLC Direct

Testing & the Six ‘Mandatory’ tests

March 21, 2017Training8 Comments

Author:

Harry Dreger, NECA Education & Careers LEA & LEI Teacher

Author:

Harry Dreger, NECA Education & Careers LEA & LEI Teacher

The Wiring Rules require that we perform these

tests on low voltage installations before they are connected to Supply. But do

they REALLY matter? Will it REALLY affect an installation? Aren’t they a waste

of time? Many electricians feel they are, and it’s not worth their time.

So

are they important? YES!! Why?? To ensure the correct and safe (ongoing)

operation of an electrical installation. That is their purpose, and this is

what it’s about:

1. Test the continuity of the earthing system. Put simply this ensures that an ‘earth’ exists and it is suitable to ensure the fuse/circuit breaker

will operate before a piece of ‘faulty’ equipment becomes ‘live’, potentially

killing somebody.

2. Insulation resistance. If this is too low, we risk equipment

inadvertently becoming ‘live’, fires and overheating from ‘leakage currents’,

and ‘equipment damage’ (particularly with electronics in equipment today.

3. Polarity. To

ensure ACTIVE (A), NEUTRAL (N) and EARTH (E) wires are in the right position.

Does that matter? Yes! I.e. swap A and E and risk

livening the frame of a piece of equipment and somebody can die. Or, put the

earth wire in the wrong place and it will carry load current, melt and cause a fire. (Remember, the earth wire is often

smaller than the A and N.)

4. Correct Circuit connections. Ensures that circuits are not suitably

connected in such a way that may cause safety hazards or incorrect operation. I.e. A piece of equipment being inadvertently connected to

two (2) sources of supply is potentially life threatening to an electrician

working on the circuit.

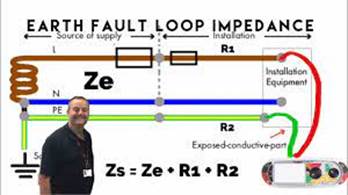

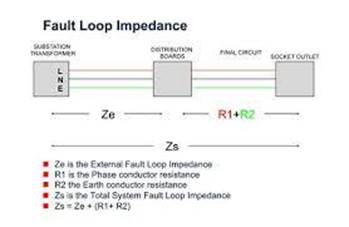

5. Fault loop Impedance. (This is associated closely with voltage

drop). The Wiring Rules mandate that under fault, a maximum voltage of 50 V can

exist on a piece of equipment for no longer than 0.4 seconds before the circuit

protection operates (see touch voltage). If the fault loop impedance is

incorrect, this will not happen.

6. Operation of R.C.D.s. Under the wiring rules, R.C.D.s are

(currently) only required to be fitted to certain circuits where it has been

deemed that safety is ‘more than normally’ likely to be a concern, i.e. kids sticking a fork in the toaster or socket outlet

etc. For that reason it is crucial to ensure the

R.C.D.s installed actually operate.

Video

https://www.youtube.com/watch?v=LcJu2tlhpiI

https://www.youtube.com/watch?v=ScD3Y1Ty5n8

https://www.youtube.com/watch?v=ZQuwbnyxPaY

https://www.youtube.com/watch?v=P-D6chUrRNk

https://www.youtube.com/watch?v=lmEnAYFSuzs

https://www.youtube.com/watch?v=xH5FxehSpM4

https://waypointinspection.com/what-is-reverse-polarity/

Insulation Resistance

What is insulation

resistance test?

An insulation

resistance (IR) test measures the total resistance between any two

points separated by electrical insulation. The test, therefore, determines

how effective the dielectric (insulation) is in resisting the flow of

electrical current.

What is the minimum

acceptable value of insulation resistance?

Insulation

resistance should be approximately one megohm for each 1,000 volts of

operating voltage, with a minimum value of one megohm.

Video

https://www.youtube.com/watch?v=TdeU6UCCfTY

https://www.youtube.com/watch?v=Ek1u2RjQffU

https://www.youtube.com/watch?v=FV0QavM9sN8

https://www.youtube.com/watch?v=yY8nsGn2xBo

https://www.youtube.com/watch?v=wxSL6oDkhGU

https://www.youtube.com/watch?v=_-n6BiFJy8w

https://www.youtube.com/watch?v=2_zHb0QvlUg

https://www.youtube.com/watch?v=eRE_8njFxZs

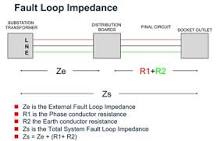

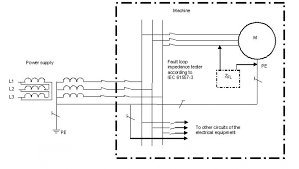

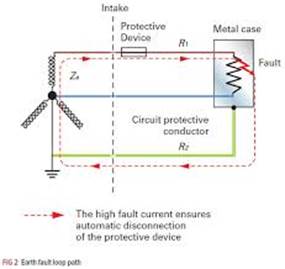

Fault Loop Impedance

What is a fault

loop impedance test?

Loop testing

demystified. ... The main reason for earth loop impedance testing – which is

often simply called loop testing – is to verify that, if a fault occurs

in an electrical installation, sufficient current will flow to operate the fuse

or circuit breaker protecting the faulty circuit within a predetermined time.၂၀၁၅- အောက် ၁

https://www.youtube.com/watch?v=_twVvsGo81A

https://www.youtube.com/watch?v=F3rw1KwFboQ

https://www.youtube.com/watch?v=d6AI_RNTTdw

https://www.youtube.com/watch?v=Ax1MzklVtI0

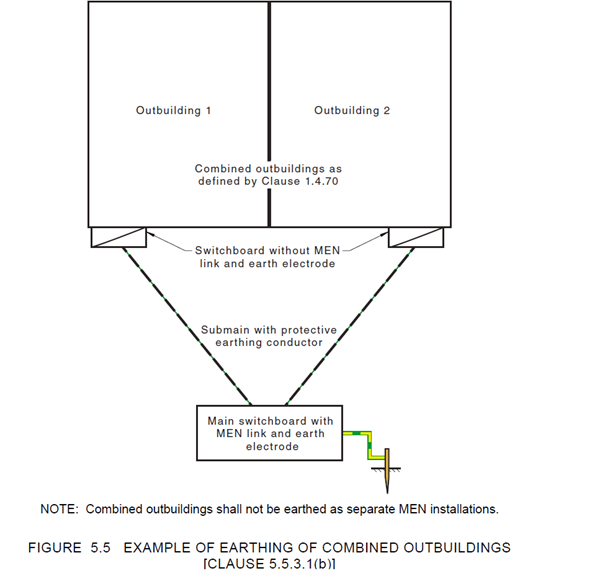

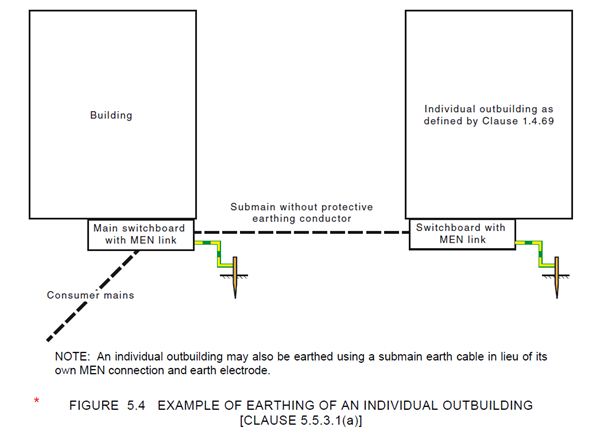

Submain Polarity

Testing for correct polarity

Several installations have been identified where

either people at the property, or at another property, have received electric

shocks due to incorrect polarity of consumer mains or submains.

Incorrect polarity connections on consumer mains or

submains supplying an outbuilding with a separate multiple earth neutral (MEN),

will result in an energised earthing system.

Testing will ensure any incorrect connection is

identified and rectified, to prevent the risk of electric shock.

The protective earth neutral (PEN) is the most

important earthing conductor in an electrical installation. The impedance of

the PEN must be low enough to pass the current necessary to operate the

overcurrent protective device and be consistent with the length, cross

sectional area and type of conductor material.

Correct polarity testing for low voltage

connections to an electricity network or where an electrical installation in an

outbuilding has a separate MEN connection in accordance with AS/NZS 3000:2018,

Clause 5.5.3.1(c) must:

- include

a visual inspection

- ensure

the use of suitably designed and correctly rated test equipment

- ensure

an effective independent earth is used

- ensure

that any neutral bonding conductor (i.e.to raiser bracket) is disconnected

- prove

the operation of the test equipment before and after testing

- prove

the identity of the incoming active conductors

- prove

the identity of the incoming neutral conductor

- prove

the integrity of the supply neutral and connections

- confirm

phase rotation

- ensure

that any bonding conductor removed for testing is tested and reconnected

- ensure

that all conductors are correctly connected, including the MEN connection

- ensure

a final visual and verification of correct connections is completed.

For detailed information and guidance on conducting

a polarity test for supply to electrical installations and neutral integrity

tests for supply to electrical installations, refer to AS 4741 (Testing of

connections to low voltage electricity networks).

Remember, polarity testers which are connected to a

final subcircuit do not confirm mains polarity and will indicate that polarity

is correct even if there is a reverse polarity.

Mains polarity verification testing

6 December 2018

We’ve added two new

how-to infographics to the Electrical Workers Toolbox that demonstrate safety

verification polarity tests with the use of an independent earth probe.

The Multiple Earth

Neutral (MEN) system we have in New Zealand is only safe if the polarities of

both the supply system and the installation are correct and the connections of

the neutral conductor are reliable.

The wiring rules AS/NZS

3000.2007 list the compulsory electrical tests required to be carried out on an

installation, one of which is polarity testing on mains and submains.

Transposed conductors in

the consumer mains or a disconnected main neutral to an electrical installation

can create significant risks of shock or electrocution, and property damage

through overheating and fire.

Polarity testing is absolutely critical and therefore must be independently

verified by the installer, inspector, and person making a connection to an

electricity supply.

The underlying principle

of mains polarity testing is to carry out all the necessary tests and checks

that will ensure the phase and neutral conductors are not transposed, and that

the neutral is continuous and earthed.

Never liven mains to

carry out live polarity testing unless correct polarity has first been proven.

Failure to do so can create an immediate and serious risk of electrocution,

shock, or fire should the mains conductors be transposed. The safety

verification polarity test is only to be carried out after correct polarity was

previously established.

These tests and other

practical guidance have been provided to assist electrical practitioners to

achieve safe, compliant and competent electrical work,

and to promote continued improvements in those areas.

Guidance on mains

polarity testing is provided in standard AS/NZS 3017:2007 Electrical

Installations – Verification Guidelines. This standard is freely available to

all licensed practitioners through a RealMe login

from the EWRB

homepage.

Consumer Main Polarity

TESTING

FOR REVERSED POLARITY

BY PAUL SKELTON

28/06/2011

In the last edition of Electrical Connection we

ran an article highlighting the growing number of reported reverse polarity

incidents in Victoria in the past year, particularly surrounding the

installation of new metering equipment.

While the danger is very

real, and the number of incidents is assuredly growing, it turns out that the

information we were presented isn’t relevant to the vast majority (99.9%) of

Australian installations.

Institute of Electrical Inspectors

life member and former Electrical

Connection contributor George Bosomworth says: “The test

described does not prove what is claimed when applied in Australia or New

Zealand (i.e. where the system of distribution used is

our multiple earth neutral, MEN, system).”

The test described is only

valid where the MEN connection is upstream of the reversal of polarity, he

says.

“In the US there are many

situations where this test would be valid – but not so in Australia or New

Zealand.

“To put it simply, if the

neutral and earth (US ‘ground’) are connected together

downstream of the meter (as is the case for our MEN system) and the active (US

‘hot’) is transposed for the neutral upstream of that point, both the neutral

and earthing conductors within the installation will be at the same

(active/hot) potential.

“Therefore, testing voltages between

the pins of an outlet (US receptacle) will indicate identical values whether

the polarity is reversed or not and the fault will not be detected (i.e. with supply at correct polarity; A – N = 230V, A – E =

230V, N – E =~0V. Polarity reversed upstream of MEN connection; N – A = 230V, N

– A = 230V, A – A =~0V.)

“For a test at an outlet to

be valid in Australia/NZ, the reference point for testing must be an

independent connection to mother earth (the soil) at a point clear of any

material that could be connected electrically to the installation, such as

underground water piping, etc. Typically a large

screwdriver shaft driven into the soil may be used.”

This leads to the next point

that often arises in such a discussion, he says: “Reliance on the main earth.”

“Many would say that the main

earth will cause a fuse to blow. This would rarely be the case.

“Typical earth resistances

for single electrodes driven 1.2m deep are in the range of 50Ω to

100Ω (or more). If we apply the nominal 230V to such a resistance Ohm’s

Law dictates that the current flow will be in the range of 2A to 5A. Even if

the earth resistance is lowered to 10Ω the current will only be 23A.

Hence, relying on the main earth to operate protection is a fallacy.”

A further issue arising from

all of this is the MEN system itself.

“When that system of

distribution was adopted, the reticulated water system consisted of metallic

piping that, when used as the main earthing system, acted as a backup to the

supply neutral conductor.

“With the advent of

non-conductive water reticulation and the use of single earth electrodes there

is now no back up for the supply neutral and hence the rise in neutral related

problems such as shocks.

“It may be that this system

of distribution needs to be reviewed.

“The requirement to earth the

neutral at each installation arises from the need to keep the supply neutral as

close to true ground potential as practicable. (If there was no such connection

the voltage between ground and the supply neutral would be about half that of

the voltage drop along the length of the distribution circuit – think about

it).”

Thus this

requirement more correctly sits with the distributor.

“If

this were to be the case, an RCD with a tripping current in the order of 300 –

400mA used as a main switch would protect the customer’s installation in the

event of a supply neutral failure.”

How do you conduct

a polarity test?

The Polarity Test

sequence:

- Select a GS 38 approved

voltage indicator and locate the Main Switch. Test between Line and

Neutral terminals.

- Test between Line and Earth

terminals.

- Test between Neutral and Earth terminals.

Video

https://www.youtube.com/watch?v=PtmqaolzPL0

https://www.youtube.com/watch?v=I8FH9iTr-vs

https://www.youtube.com/watch?v=IS-C5hwJ-tI

https://www.youtube.com/watch?v=I8FH9iTr-vs

https://www.youtube.com/watch?v=X5VEtGTSrwg

Intermix Circuit

https://www.youtube.com/watch?v=AZenZfLQQgw

Safe isolation

The procedure

for proving dead should be by use of a test lamp or two pole voltage detector as recommended in HSE Guidance Note GS38.

Non-contact voltage indicators (voltage sticks) and multi-meters should not be

used. The test instrument should be proved to be working on a known live source

or proprietary proving unit before and after use. All phases of the supply and

the neutral should be tested and proved dead.

Test sequence

and descriptions

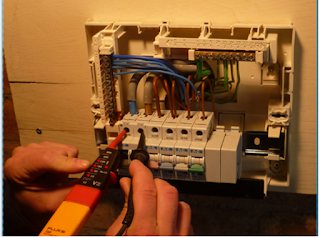

The following

tests are carried out with the Consumers main switch isolated

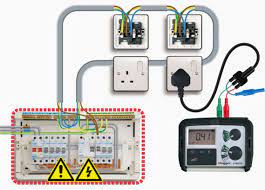

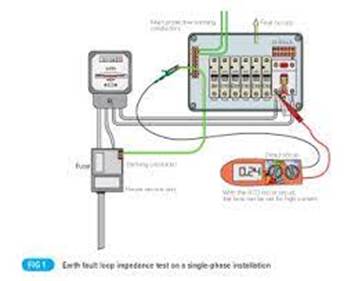

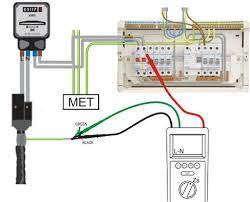

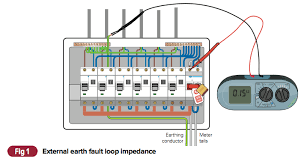

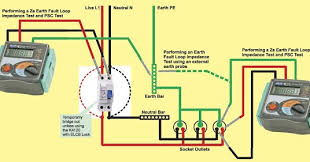

1. Extenal earth fault loop impedance

Reason: To

establish that a good earth exists at the installation in

order for the remaining tests to go ahead.

Method:

Disconnect the main earthing conductor from the main earthing terminal. An

earth fault loop impedance tester is connected at line and earth (main earthing

conductor) at the supply side of the installation and a test performed.

Reconnect the main earthing conductor. The result is Ze and recorded on the

sheet. The prospective fault current is measured at the same time after the

reconnection of the main earthing conductor.

2. Continuity

of protective and bonding conductors

Reason: To

check that all circuit protective conductors (green and yellow cables) are

continuous and are present at every electrical accessory on the circuit. Also to check that the main earthing conductor and main

bonding conductors are continuous and correctly connected.

Method 1: The

line conductor is connected to the circuit protective conductor of the same

circuit at the consumer unit and a measurement taken at ALL accesories

on that circuit between line and c.p.c. The highest

measurement obtained is recorded on the test report.

Test result is R1 + R2. The line conductor and neutral conductor are then

connected and the above repeated to obtain R1 + Rn

Method 2 (used

for main earth and main bonding conductors): A wandering lead is connected to

one end of the conductor to be tested and a measurement taken between the other

end of this lead and the other end of the conductor.

Test result is R2.

During this test polarity can be checked as well. The continuity of the neutral

conductor can also be checked.

3. Continuity

of ring final circuit conductors

Reason: This

test ensures that all ring final circuits (sockets usually) are indeed a

continuous ring with no interconnects or breaks within it.

Method: The

line, neutral and earth conductors of the circuit are identified and a

measurement from one end to the other end of each is taken. These results are

r1, r2 and rn.

The incoming line conductor is then connected to the outgoing earth conductor

and the outgoing line conductor is connected to the incoming earth conductor. A

measurement is then taken at ALL socket outlets on the ring. The highest of

which is recorded on the report.

This result is R1+R2 for that circuit. The above is then repeated using the

neutral conductor instead of the earth conductor. This test provides R1+Rn

which does not need to be recorded on the report but is essential to check the

circuit correctly.

4. Insulation

Resistance

Reason: This

test checks whether the insulation around a cable is still intact and has not

broken down over time. It is a good indicator of the age of an installation.

Method: An

insulation resistance tester is connected across line and neutral tails at the

origin of the supply. 500V are then pumped down the conductors to see if any

voltage leaks across from one conductor to the other. The same is then done for

the line and earth and the earth and neutral conductors.

5. Polarity

Reason: To

check that all accesories are correctly connected to

line, neutral and earth and that all switches and circuit breakers are

connected in the line conductor only.

Method: The method

for this is the same as for continuity and is usually done at the same time by

operating switches etc whilst conducting the test.

6. Earth

electrode resistance

Reason: To make

sure that any earth electrode used is of a sufficiently low impedance to allow

the timely operation of the RCD protecting the installation.

Method: An

earth fault loop impedance tester is connected between line and earth at the

origin of the supply and a test performed. The result of which is considered

the resistance of the electrode (Ra).

The following

tests are carried out with the Consumers main switch energised

7. Live

polarity test

Reason: To

verify polarity of supply authorities system.

Method: An

approved voltage indicator shall be used or test lamp to GS38. Using the

approved voltage indicator, one probe shall be placed on the incoming neutral,

and the other on the incoming line conductor, on the main breaker. The

indicator should show it is live. One probe shall now be placed on the CPC and

the other on the incoming line conductor. The indicator should show it is live.

A test shall be preformed between CPC & incoming

neutral. The indicator should show that it is not live.

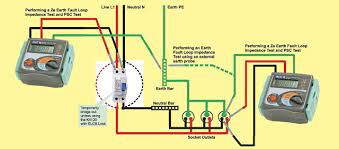

8. Earth fault

loop impedance

Reason: This

test is done at the furthest point on a circuit in order to make sure the

impedance of the earth path is not too high even at the furthest point so that

sufficient current will flow under fault conditions to take out the circuit

breaker protecting the circuit.

Method: An

earth fault loop impedance tester is connected to line and earth at the

furthest point on the circuit and the test performed.

9. RCD test

Reason: To make

sure RCD's trip within the correct time

Method: An RCD

tester is connected and a test at 1/2 times, 1 times

and 5 times the trip current is performed on each side of the cycle and a time

of trip obtained. Usually milli-seconds with the highest being recorded. The

manual test button is then pressed.

10. Functional

testing

Reason: To make

sure all switches, isolators, MCB's etc. work as they should.

Method. Self explanatory.

Correct Circuit

Connection

Electrical polarity (positive and negative) is the

direction of current flow in an electrical circuit. Current flows from the

positive pole (terminal) to the negative pole. ... In the context of

electricity installations, a polarity test is used to confirm the correct

connection of the line and neutral conductors.

UEEEL0039

|

2.Select wiring systems, cables, control and protection for general electrical

installations |

|

G063+G107 |

http://www.highlightcomputer.com/electricaltrade2021.htm#G063

http://www.highlightcomputer.com/electricaltrade2021.htm#G107

3.Install low voltage (LV) wiring and

associated accessories

G103+G104

http://www.highlightcomputer.com/electricaltrade2021.htm#G103

http://www.highlightcomputer.com/electricaltrade2021.htm#G104

4.Install and connect LV appliances, switchgear and associated accessories

G063+G033

http://www.highlightcomputer.com/electricaltrade2021.htm#G063

http://www.highlightcomputer.com/electricaltrade2021.htm#G033

Capstone Test Questions

Capstone_Practical_Tutorial_Questions

Capstone

Practical Test Question Version 4

Capstone

Practical Test Question Version 5

REFERENCE NOTES

ACA-Testing-electrical-installations-Final-2014

crn-sc-010-inspection-and-testing-procedures-v11-apl-2016

Protection_Methods_Week_2_G063A_V1.4

VESI-Installation-Supply-Connection-Tests-and-Procedures-June-2017